It appears that there is a lot of misunderstanding regarding the difference between inventory and warehouse management.

Despite the fact that they appear to be referring to the same kind of materials management, there are actually some significant variations between the two.

It is essential for businesses to have a solid understanding of the distinctions that exist between inventory management and warehouse management.

It is because the kind of materials management system that you use to catalog your inventory is contingent upon a variety of factors, any one of which can have an impact on the efficacy of your company.

What is Warehouse Management system?

The many processes involved in maintaining and regulating a company’s warehouse are referred to as warehouse management.

It goes through the entire process, from start to finish, and is frequently supervised by warehouse managers.

Warehouse management involves everything that happens in a warehouse, from receiving freight to asset tracking and logistics.

Businesses may manage their whole warehousing operations, whether they own one warehouse or multiple. All of these duties can be aided by a Warehouse Management System (WMS).

What is Inventory Management system?

The process of managing an organization’s inventory includes maintaining a record of the stocked items. It keeps track of their dimensional makeup, quantity, as well as their location.

It provides owners of businesses with the information they need to determine whether it is appropriate to replace products or purchase additional materials to create them.

A company must have efficient inventory management in order to guarantee that it has sufficient goods on hand to fulfill the requirements of its customers.

If inventory management is not handled correctly, it is possible for a company to either lose money on potential sales that can’t be fulfilled or waste money by keeping too much goods than is necessary.

Both of these outcomes result in the loss of financial resources. These types of errors may be avoided with the assistance of an inventory management system (IMS).

The difference between inventory system and warehouse system

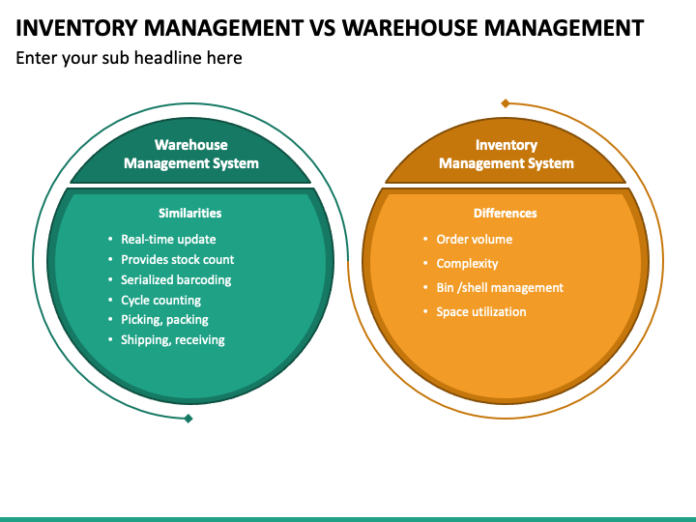

In a summary, the fundamental distinction between an inventory management system (IMS) and a warehouse management system (WMS) is that the former entails tracking counts of individual products or SKUs, while the latter entails tracking units of space, such as compartments and bins.

In other words, a WMS tracks counts of individual products, while an IMS tracks counts of space.

If you had your own warehouse and stored items that were relatively large, for example, something that was large enough to fill an entire bin or compartment, you probably wouldn’t need an inventory system because it would be relatively easy to keep inventory using the WMS and count stock by hand.

However, if you didn’t have your own warehouse and stored items that were relatively small, you probably would need an inventory system.

On the other hand, if you had a number of smaller products, such as packs of gum, and you knew exactly how much space various quantities of gum used up, then you might be able to get away with using only an IMS. This is because you would be able to manage your space based on the inventory counts that you perform.

In spite of all of that, there are some things that you simply cannot accomplish in any of those two scenarios without making use of both of those systems.

Although it is possible that you could get away without doing a physical count of your large warehoused products, having an IMS eradicates the need to do physical counts entirely, at least until the time comes for the inventory to be audited.

Even though you are doing a good job of controlling the space for the gum, there is still a possibility that you are squandering more warehouse space than you realize in the gum case.

The distinctions between a warehouse management system and an inventory management system are outlined below.

Complexity / Features

The level of sophistication that each form of inventory system requires is one of the key distinctions that can be made between inventory management and warehouse management.

In the sense that an inventory management system is able to provide you with an estimate of the entire quantity of stock that you have at a certain storage site, this type of system makes managing inventory a little bit less complicated.

On the other hand, warehouse management systems give a corporation the capacity to control the entirety of the storage systems that are included within a building such as a warehouse.

A warehouse management system will be able to assist you in managing several storage bins of the same product, but an inventory management system will just be able to tell you how many of a certain product you have in stock.

Control and Storage

The difference between how easy something is to do and how difficult it is to do also applies to the management and storage of inventories. You can essentially only learn two things from an inventory management system: whether or not you have a certain product in stock and how much of that product is available.

The use of warehouse management software is essential to the effective administration of inventory within the warehouse. This software makes it possible to locate particular areas in which to store goods and even to recover it at a later time.

In a nutshell, warehouse management provides the particulars of inventory control, while inventory management merely provides the number of the items in question.

Integration

The degree to which a single system may be incorporated into the broader logistics of a company’s management of its supplies and inventory is another significant distinction between inventory management and warehouse management.

According to SAP, inventory management is typically the initial step in the various activities that are carried out during warehouse management. [Citation needed] Nevertheless, warehouse management is intricately intertwined with other facets of firm administration, including manufacturing supply, sales and distribution, and quality control.

In other words, inventory management is not essential to the day-to-day operations of other departments, whereas warehouse management is.

Software Solutions

When comparing inventory management software to warehouse management software, one thing to keep in mind is that inventory management software typically does not do this, whereas warehouse management software typically provides a company with the opportunity to analyze and adjust its inventory and storage in accordance with the requirements of the business.

The use of a variety of communication devices in warehouse management generally makes it feasible to conduct analysis and make adjustments as required, which ultimately results in an operation that is more streamlined and effective.

Software Solutions Key Differences

The crucial difference between an inventory management system (IMS) and a warehouse management system (WMS) is that the former involves the tracking of counts of individual products or SKUs, while the latter involves the tracking of units of space, such as compartments and bins. A WMS is abbreviated as “WMS,” while an IMS is abbreviated as “IMS.”

Inventory management software

Inventory management software is a computer-based system that keeps track of inventory, orders, sales, and deliveries.

It can also be used to create work orders, bills of materials, and other production-related documents in the manufacturing industry. This program is ideal for businesses searching for a less complicated inventory management system that focuses on the physical goods itself.

Inventory management software is excellent for small to medium-sized firms with a limited product variety. The fact that this software’s features are confined to inventories is perhaps its biggest advantage.

Inventory management software is suitable for a business that doesn’t require all of the bells and whistles of a more complex management system.

Warehouse management software

Warehouse management software, similarly inventory management software, can track product quantities, cycle count, pick, pack, and ship orders, as well as manage numerous locations.

Warehouse management software, on the other hand, provides more information and capabilities related to product delivery, channel listing, and other features. In reality, warehouse management software contains so many features that describing them all in one piece would be difficult.

Overall, warehouse management software features provide users with information on items and warehouse processes that can be utilized to make warehouse efficiency assessments. This software’s capacity to track online inventory across numerous channels is another important feature.

Warehouse management software is primarily intended to improve warehouse operations. However, this software serves another important purpose.

Inventory tracking and management can be used across numerous e-commerce platforms. This program keeps track of online inventories and sales while also synchronizing quantities across several marketplaces in real time. If you sell an item on one site, the sale will be deducted from the quantity of the product on all markets.

Conclusion

When determining whether to utilize inventory management software or warehouse management software, purchasers need to determine which option is most suitable for their particular type of business.

There are significant differences between these software programs, despite the fact that their names are very similar to one another. There are significant differences between the methods in which inventory management software and warehouse management software achieve their respective goals of reducing the likelihood of errors caused by humans and maximizing productivity.