Aluminium powder coating is one of the best and most efficient technologies that enhance the look of aluminium products and also provide them with far better functionality. This is done by applying a dry powder on the outer skin of the aluminium and making the covering go through a process of being heated till it becomes a solid. The coating improves the corrosion, scratch and environmental resistance of aluminium products, this aluminium powder coating is also safe for the environment since it does not emit VOC and they provide varieties of surface covers such as matte and shiny.

Today, powder coating has found its application in many sectors of manufacturing because it gives a better finish than wet painting. For instance, they use it in the construction of buildings and structures, car industries, and the production of other products that are needed by humans among others.

1.Advantages of powder coated Aluminium extrusions

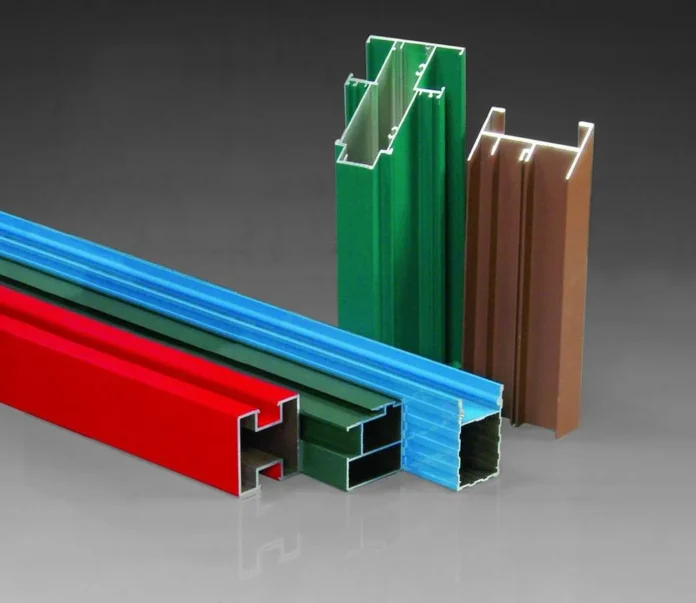

Extrusion is also very effective in improving aluminium products which are common in construction, transport and production industries. Products made through this method include; Extrusions are obtained by forcing the aluminium between a die to get the required shapes and thickness. And if they are powder coated the extrusions are even more hardwearing and aesthetically pleasing making them even more appropriate to be used. Hence powder coated aluminium extrusions unlike painted aluminium extrusions that can peel, chip or fade are ideal for internal and external applications. It also protects against unfavourable conditions such as ultraviolet light or salt water and moisture. Furthermore, the various colours and textures of options make the extrusions highly versatile and aesthetic in addition to their practical uses.

2.Durability and resistance in powder coated Aluminium

Aluminium powder coating has a very useful property in that it is highly durable. It functions like a shield which enhances the inherent properties of the metal favouring corrosion, adhesion and physical shocks. Earlier, it has been noted that aluminium has the innate feature of being able to withstand corrosion and that powder coating accomplishes the added extra protective layer where the aluminium is likely to come into contact with water, chemicals or varying climates. Also worthy to note is the fact that aluminium extrusions come powder coated or painted and such surfaces can never be exposed to problems of UV or wear and tear whereby the surface has to peel or change color. This feature also results in less maintenance cost since powder-coated surfaces do not need to be repainted or repaired often compared to paint on cars, for example.

3.The following are the environmental benefits of Aluminium Powder Coating

The factor of sustainability is rapidly gaining traction in many industries, and an aluminium powder coating is especially beneficial in the following aspects: About the degree of solvent emission, powder painting has still fewer emissions than liquid painting. Powder coating does not require any solvent solutions to dissolve the powder which means that does not release any volatile organic compound into the environment like coating solvents do. Also, any additional powder that could be used in the coating process can be collected and used again which would minimize wastage. Aluminium itself is relatively easy to recycle and when combined with powder-coated finishes it is an assurance that the environment will suffer no harm. From an environmental point of view, powder-coated aluminium extrusions are equally a good thing for businesses to adopt.

4.Versatility of powder-coated aluminium extrusions

Alminium extrusions also carry the ability to be powder coated, this displays immense durability allowing the product to be used in various applications. Aluminium extrusions can also be in various shapes, sizes and profiles therefore can be used in construction, automotive parts, electronics, and furniture. This versatility is however taken to a new level with Powder coating which can be effected in numerous colours and finial to suit the project at hand. Various windows, doors, façade and frame positions powder-coated aluminium extrusions are used because of their lightweight strength and appearance. They can effectively be cut or welded, and formed into the required profile or size, without affecting the performance of the powder coat application and therefore durability of the extrusions is not compromised.

5.Cost-Effectiveness of Powder Coated Aluminium

Aluminium powder coating is comparatively expensive at the time of application but has hailed numerous advantages in terms of its cost in the long run compared to painting. This is because the aluminium extrusions that have been powder coated have a longer span than other similar items since the powder coated is much better as it is a coat of paint or other similar surface finishing. This means less repair or repainting required over a long period, lowering additional expenses the more. The process of powder coating is also considered very efficient by itself. The powder binds to the Aluminium part uniformly and there is little or no wastage and the Aluminum surface These coatings take a very short time to dry up, unlike most other coated products in the market. Also, it may further be explained that, as powder-coated aluminium products have a long life span, it can be seen that it is worth investing in these products for those industries that aim to have long-lasting products.

6.The Process of Powder Coating and Methods

The aluminium powder coating process involves various procedures that enable the substrate metal to stick well on the coating. To start with the aluminium extraction is washed to remove any dust, oil or any other form of dirt that might be present. Often this cleaning process involves the use of chemicals or use of sand blasters in preparation for the coating process. Aluminium is then cleaned and is made ready for the application of the powder coat.

The powder coating is applied with an electrostatic spray gun and is charged so that it will stick to the earthed aluminium substrate. Once the powder is on, the aluminium is taken into an oven where the powder melts and runs and forms a uniform layer. The outcome is a strong, beautiful material that can be used again for architectural purposes as well as interior and industrial production.

7.Peculiarities of Further Development Powder-Coated Aluminium Products

While inustries are developing, the need for new materials as well as environmentally friendly materials is rising all the time. Aluminium profiles that are powder-coated are anticipated to be a very important element in construction and design in the future. New developments in energy efficiency, in particular energy efficiency in construction, have led to greater use of aluminium in construction because of its lightweight but high strength. These properties are improved by powder coating and hence make it ideal for use in the production of sustainable buildings., they also hold high expectations for the development of the technology in powder coating because of the enhancement in the function and the appearance of the aluminium products. Remarkably, aluminium extrusions are gradually used in several different industries because the outcome of the powder coating gives elevated protection from corrosion, chemicals and heat, and now they are striving to make new types of coating which means that the potential uses of aluminium extrusion is almost boundless.

Powder-coating aluminium and powder coated aluminium extrusion have several advantages which have been implemented in several sectors. This means powder-coated aluminium lasts longer, is environmentally friendly, cheaper and can be used in many designs selected by architects, engineers and manufacturers. Due to the recent innovations in technology and ever ever-rising need for sustainable products powder coated aluminium is anticipated to continue occupying its strategic position in modern aesthetics and architecture.